|

Acronym: DYMATCO

Project code: PN-III-P2-2.1-PED-2019-1885

Funding programme: Competitiveness through research, development and innovation

Subprogram: Demonstration experimental project

Project leader: Dr. Stiubianu George

Duration: 21 months

The aim of DYMATCO project was to develop, through a cost-affordable approach, a laboratory technology for wearable clothing-integrated materials with passive dual-mode thermal comfort (heating and cooling). The newly developed materials will have user-controlled adaptability for integrated management of the heat flux between the body of the user and the environment. These materials use the synergistic effects of elastomers and nanometer-sized metallic structures integrated within clothing made of usual textile materials (such as cotton, polyester, etc).

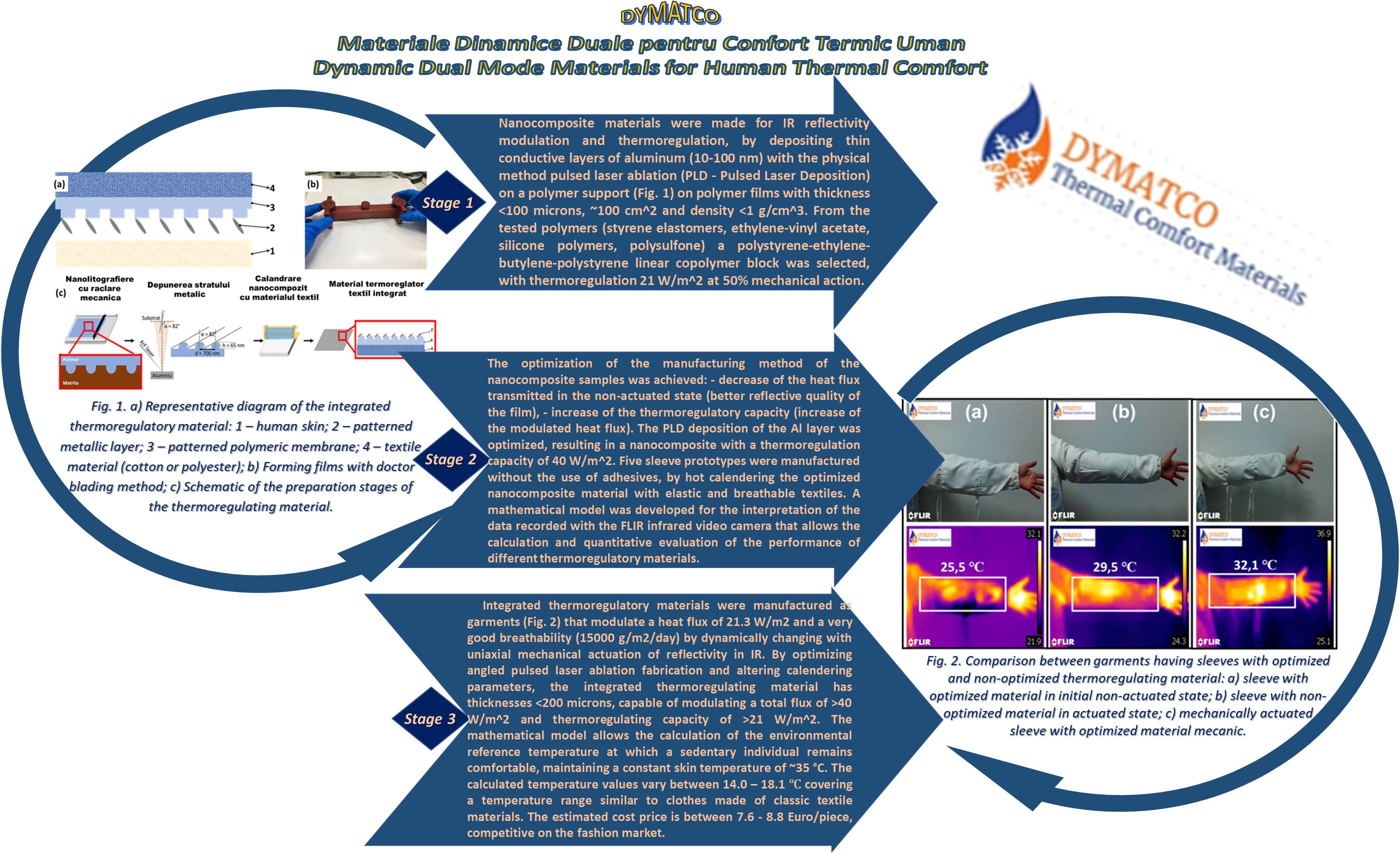

In the first stage of the project, nanocomposite materials with adaptive infrared (IR) reflectivity and thermoregulation by uniaxial mechanical actuation were fabricated by depositing on polymer support thin conductive layers of aluminum or aluminum doped zinc oxide (10-100 nm) through the physical method of pulsed laser ablation (PLD - Pulsed Laser Deposition). Polymer films less than 100 micrometers thick with an area of about 100 cm^2 and a density of up to 1 g/cm^3 have been obtained. From the 10 classes of polymers tested (styrene elastomers, ethylene-vinyl acetate, silicone polymers by ring-opening polymerization followed by cross-linking by condensation reactions, hydrosilylation or thiol-ene addition, polysulfone) was selected a polystyrene-ethylene-butylene-polystyrene linear block copolymer elastomer (12% styrene), with thermoregulation capacity of 21 W/m^2 for uniaxial mechanical actuation of up to 50%.

In the second stage of the project, the optimization of the manufacturing method of nanocomposite materials was achieved, aiming at the decrease of the heat flux transmitted in the unactuated state (better reflective quality of the film), as well as the increase of the thermoregulatory capacity (an increase of the modulated heat flux). IR reflective film growth and deposition properties of Al thin film were optimized by reducing target-substrate distance and changing laser parameters used in PLD. A nanocomposite material with a thermoregulation capacity of 40 W/m^2 was obtained. Five sleeve prototypes were fabricated without the use of adhesives by hot calendering the optimized nanocomposite material with elastic and breathable textiles, and the cost price for such garments was calculated. A mathematical model was developed for the interpretation of the data recorded with the FLIR C2 infrared video camera for rapid calculation and quantitative evaluation of the performance of different thermoregulatory materials.

In third stage of the project, integrated thermoregulatory materials were manufactured in the form of garments with the ability to manage the heat flow of 21.3 W/m^2 and a very good breathability of the material (approximately 15000 g/m^2/day), by dynamic change of IR reflectivity and thermoregulation due to uniaxial mechanical actuation. The optimization of the laboratory scale procedure with angled pulsed laser ablation and improved parameters for hot calendaring has led to integrated thermoregulating material with thickness <200 microns, modulation of a total heat flux of >40 W/m^2 and thermoregulating capacity of >21 W/m^2. Mathematical modeling allows the estimation of the temperature range in which the integrated thermoregulatory material can be actuated by uniaxial mechanical elongation and the calculation of the environmental reference temperature at which a sedentary individual remains comfortable, maintaining a constant skin temperature of ~35 °C and a flow of heat generated in equilibrium of 73 W·m-2. The calculated temperature values range between 14.0 – 18.1 ℃, thus covering a temperature range similar to clothes made of classic textile materials. The cost price assessment for such an article of clothing is in the range of 7.6 - 8.8 Euro/piece, competitive on the fashion market.

|