|

| Home | |||||

| Team Members | |||||

| Project Abstract | |||||

| Objectives | |||||

| Dissemination | |||||

|

|||||

| Contact |

Stage 2018: ![]()

Stage 1/2018 - Obtaining new biomaterials based on xanthan and polyvinyl alcohol

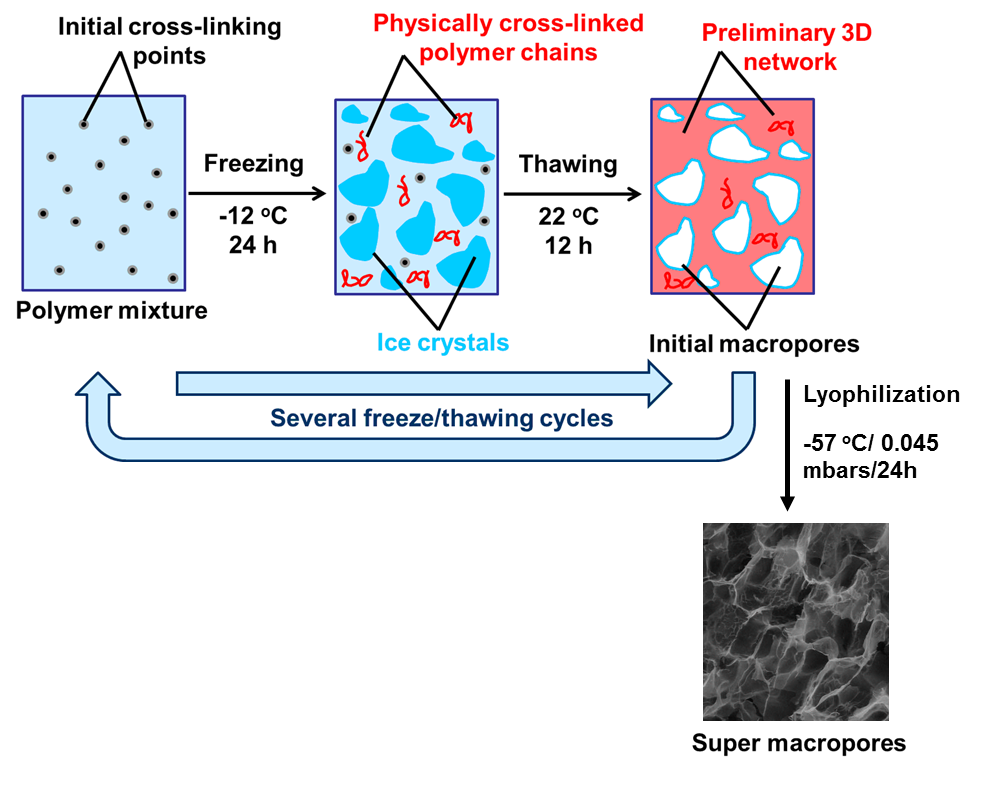

Activity 1.1. The optimal conditions to obtain the biomaterials through freeze/thaw method by using Water baths/Circulators GRANT (GR 150) will be established. The optimization of several parameters like: freezing temperature and time, also the thawing conditions which can be either in ambient air or temperature below 20 oC, is crucial in order to obtain a homogeneous mixture of the components without phase separation avoiding also freezing damage.

Activity 1.2. The PVA films with incorporated active antioxidant compunds will be obtained through freeze/thaw method, by performing several cycles in order to find an appropiate number of freeze/thaw cycles for an optimal interaction density in the polymer matrix, fact which influences the mechanical properties like: strentgh and flexibility.

Activity 1.3. The PVA/xanthan films with incorporated active antioxidant compunds will be obtained using freeze/thaw method, by varying the components concentration.

Stage results:

- In the first stage of the project, xanthan/poly alcohol vinylic cryogels were prepared and characterized, varying the component ratios and freeze/thawing cycles. Specific methods (swelling tests, DVS, FTIR, optical images, SEM, thermal behaviour) were used in order to evaluate the efficiency.

- All cryogels exhibited a heterogeneous morphology with polyhedral pore size. Using only 3 freeze-thaw cycles to prepare these cryogels, no significant influence on the pore size was observed by the addition of the antioxidant agent.

- On swelling, cryogel stability can be increased moreover by increasing the number of cycles of cryogelation or antioxidant inclusion and by judicious increase in PVA content.

- Appearance of the new peaks at 784 cm-1 and 781 cm-1 corresponding to the vibration of stretching the aromatic rings indicate the inclusion of AO in the XG/PVA cryogel network.

- The results obtained from the study of the cryogel properties with different ratio of XG/PVA have allowed the establishment of the optimal ratio in order to obtain materials that meet both the requirements for practical applications and the requirements regarding the food safety.

| Designed & Maintained by CLICK NET SOLUTIONS |